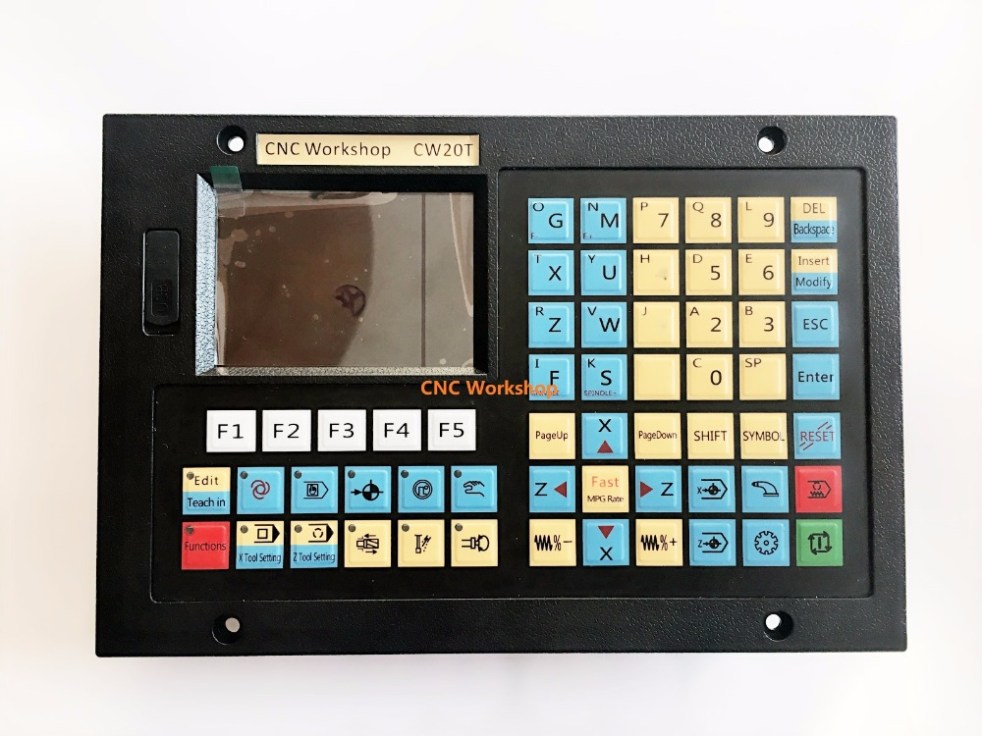

CNC4620 CNC Lathe machine control system

Introduction:

ADTECH specifically for small and medium sized machine tool manufacturers both in domestic and abroad independent research and development of cost-effective CNC control system.

Use ARM high performance CPU and super-large-scale programmable device FPGA, real-time multitasking control and hardware interpolation technology to ensure high efficiency of the system under the um-level precision machining.

256M electronic panel meets variety of large program work pieces.

7 inches color screen, interface can be made of parameter selection in both Chinese and English.

Function Specification

- Controlled axes X, Z-axis two-micron precision interpolation

- Can be configured according to different user needs stepping, servo drive, to achieve cost performance

- USB, U disk, RS232Com communication and so on the many kinds of communication methods, easy to help users to realize

- different data transfer and software upgrades

- With a network interface, support for remote monitoring and DNC file transfer process

- An open platform, can be customized according to customer’s requirements the special system.

- Perfect self-diagnosis function, internal and external state of real-time display, abnormal alarm immediately.

- Supports external additional panel, hand wheel box operation, convenient for the customer tools changing.

- Macro variables, macro definition programming, for a variety of logic relations. Support with parameters of macro program

- invocation, the user more convenient programming.

- DXF + G code template function, the DXF automatically converted to G code processing.

- Variety of ways with automatic calibration, the tools calibrate instrument etc.

- The teaching function: teaching + RISC programming, using tabular teaching mode, the teaching method is simple, intuitive.

- Graphic simulation function: Display graphics as well as the tool movement trajectory of the actual operation of the machining

- program, but does not control the machine running the simulation tool path, inspection of machining program is correct.

- Multi-interface options: Support multi-language interface display, automatic fault alarm, rich in processing information display,

- processing time, number of pieces.

- Parameter table: input and output address arbitrarily set, only need to address bar to fill in the corresponding data in the

- configuration table.

-

7 inch large color (800 * 480 pixels) LCD screen

PCI specification revision 2.2 compliant.

PCI specification revision 2.2 compliant.