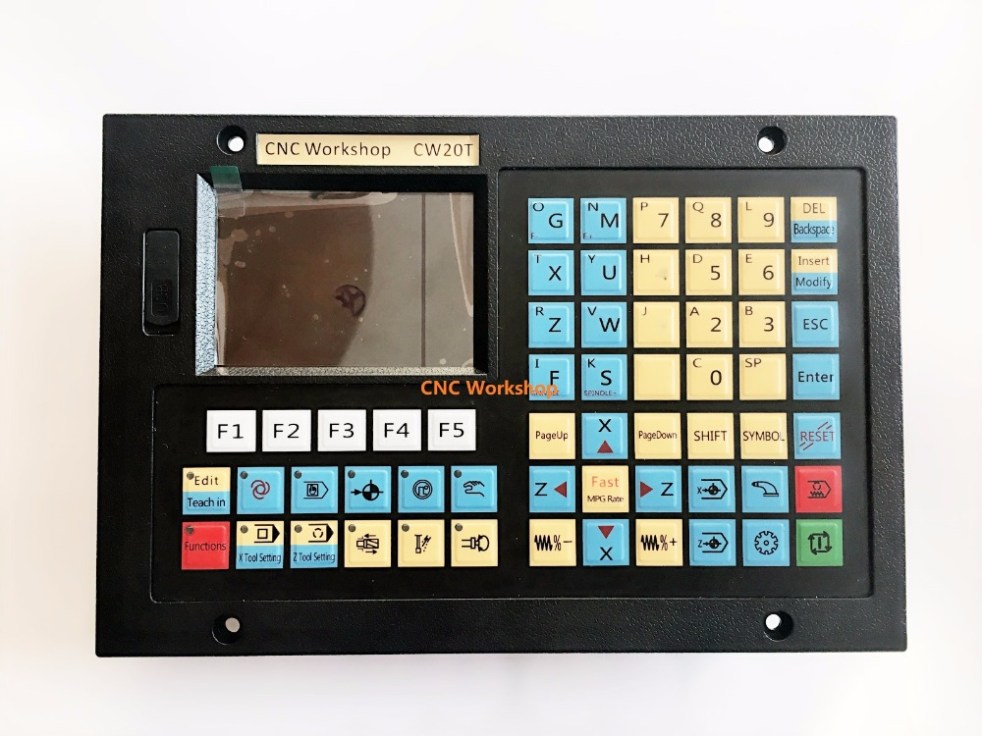

1. System Introduction

CW20T is the new generation of CNC Lathe Controller developed by TOPCNC Workshop Automation Technology. It adopts standard international G code programming, full screen editing and programming, as well as Chinese/ English operation interface. System operation is simple and intuitive, through the programming it can complete the cylindrical, end, slot, taper, arc, thread, tapping, deep hole drilling and other processing, supporting VFD spindle and servo spindle control, supporting ATC, input and output customized defining.

CNC system hardware and software features:

★ Based on 32-bit microprocessor, full linkage, 0.001mm interpolation accuracy, the maximum speed of 12 m / min.

★3.5-inch color wide screen LCD, resolution 480*320, Windows interface style. Equipped with five soft function buttons, easy to learn. Provide parameter classification, alarm log, system diagnostics and other rich display interface, easy debugging and maintenance.

★ International standard G instruction

★Support program full-screen editing, built-in 256M massive program space, can store 200 programs

★ USB interface, support U disk file reading and writing, data backup and U disk direct processing (DNC).

★ 24 input points, 24 output points (custom), flexible and convenient.

★ Chinese / English operation interface, complete help information, operation more convenient.

★Support multilevel operation authority, convenient equipment management, with time limit system lock function.

★ Can do threading, support ATC.

★Maximum Frequency for each axis:200khz

★ Support Macro